05-20-2025

Getting there faster with data: How PRÜM and GARANT get more out of their systems with “ida”

Many new production lines, many new challenges - ida provides answers.

Whether frame production, door blank presses, complex handling systems or packaging lines: Door and frame manufacturers PRÜM and GARANT (both Arbonia AG companies) have invested heavily in new production technology in recent years. The aim: more capacity, more automation, more flexibility, more productivity.

Of course, such a plant ramp-up with a large number of variants in batch size 1 also entails a high level of complexity. Short, regularly recurring interruptions, missing consumables, manual workstations that are not optimally utilized, variable process times due to a high product variance or non-optimal production sequences due to a dynamic product mix are challenges that reduce the degree of plant utilization and whose effects and causes must first be uncovered.

ida makes visible what would otherwise remain hidden

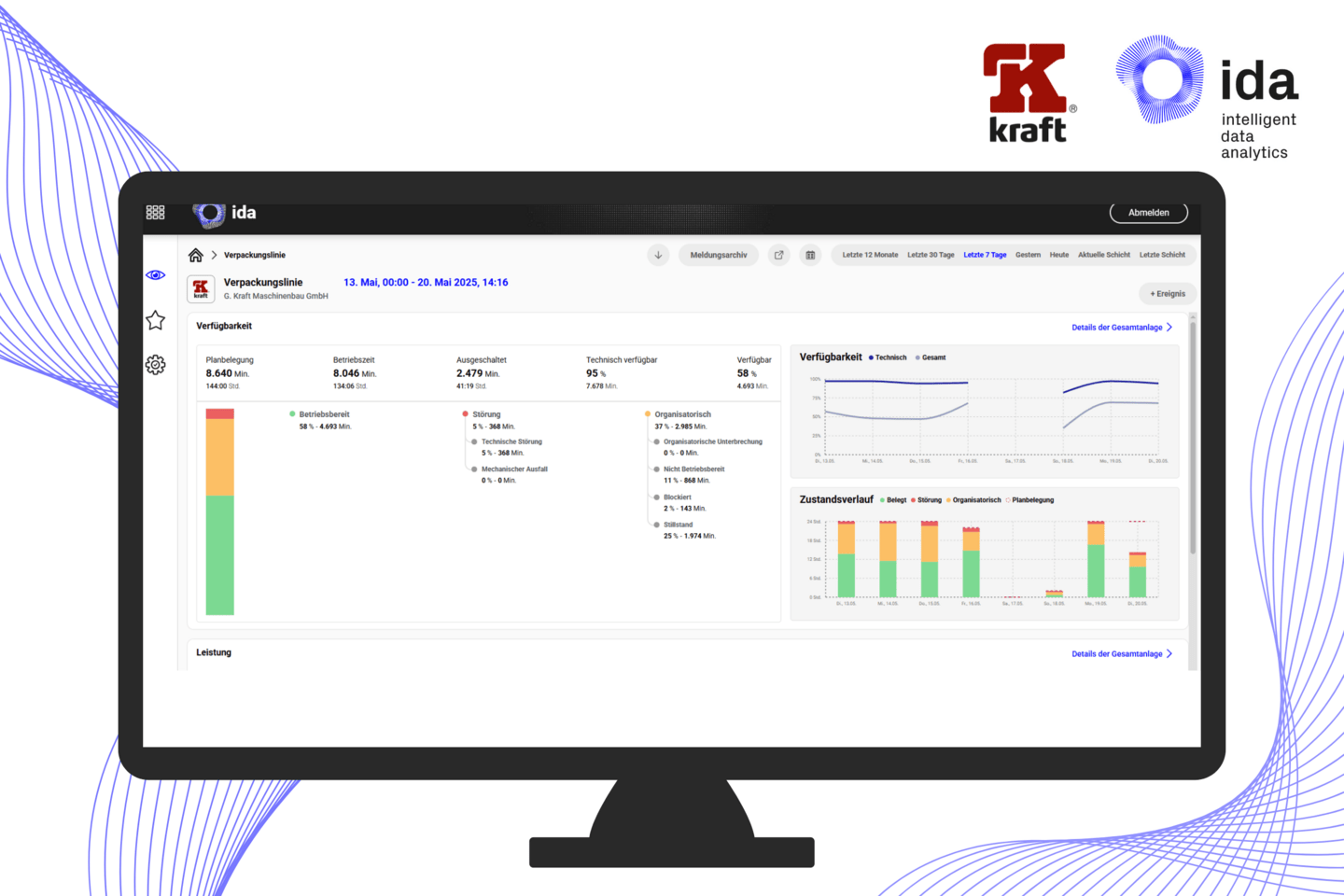

This is precisely the area in which intelligent data analytics (IDA) comes into action. The Kraft Group's software platform was specially developed for complex production lines. It makes visible what otherwise often remains hidden: Availability losses, bottlenecks, product mix - in real time, transparently, intuitively.

The solution goes straight to the source - the PLC - and provides reliable first-hand data. This information is used in ida to generate evaluable key figures such as

- Technical availability and overall availability

- Key performance indicators and product mix produced

- Cycle and product-related process times

Holistic monitoring also enables a “drill-down” analysis from the general key figures to the smallest details, e.g. losses at station level, units, sensors, etc.

10% more overall availability in just a few months

The project at PRÜM and GARANT clearly shows that ida is more than just a dashboard: the new production lines were connected directly to ida - and it paid off. The overall availability has increased by more than 10%, and that after just a few months. This is due to the greater level of transparency and the improved analysis options - a huge lever, especially in complex processes. After all, these improvements are not purely technical - they also result from the fact that organizational processes such as sequences, material provision or the timing of individual stations can be optimized in a more targeted manner. And: thanks to permanent transparency, improvements remain visible and controllable in the long term.

ida brings light into the data jungle

If you understand systems better, you can operate them better With ida, PRÜM and GARANT have found a solution that can do more than just display figures. It helps to make decisions - faster, more informed, more effective - and it makes one thing very clear: data is valuable when it is made usable.

PRÜM: www.tuer.de/

GARANT: www.garant.de/